4 min read

The Ultimate Guide to Survey Stakes: Poplar vs. Pine

Mark Villanueva

Aug 29, 2025 4:42:30 PM

Mark Villanueva

Aug 29, 2025 4:42:30 PM

You’re out on a job site in August. The sun’s already burning through your shirt at 9 a.m., and you’re driving stakes into lime-treated soil so hard it could chip a hammer. The crew’s moving fast, but snap — another stake splinters halfway in. You toss it aside, grab another, and keep going. By lunch, you’ve broken a dozen.

It’s the kind of thing most people write off as “just part of the job.” But here’s the truth: that “little” problem? It’s chewing through your budget, slowing your crew, and cutting into your profit. I’ve been in this business long enough to know that in Texas dirt, even something as humble as a survey stake can be the difference between finishing ahead of schedule or bleeding money in overtime.

And if you think all stakes are the same, stick around — because the right choice between poplar and pine could change the way you work. Keep reading to learn more, and get in touch with our supply team to talk about getting the stakes and other materials you need for your next job.

Why Stake Choice is a Bigger Deal Than You Think

Why Stake Choice is a Bigger Deal Than You Think

Ask anyone who’s been on a tight schedule: Nothing throws off your rhythm faster than a stake that snaps halfway into the ground. It’s irritating and it’s a productivity killer.

Every time a stake breaks, you’re losing a piece of wood and also:

- The time it takes a crew member to grab a replacement.

- The momentum of the job when that rhythm is broken.

- The accuracy if a control point gets lost and has to be resurveyed.

And that’s before we talk about the actual cost in dollars. On a big job using thousands of stakes, even a 15–20% breakage rate can add hundreds of dollars in replacement wood — plus hours of extra labor. It adds up fast.

The best contractors I know don’t think about stakes as an afterthought. They think about them as part of their profit strategy. And right now, the real choice in Texas comes down to two players: pine and poplar.

Here’s the rundown on what you’re really choosing between:

Pine: The Trusted Ol’ Faithful

Pine: The Trusted Ol’ Faithful

For decades, pine has been the go-to stake for southwestern survey work. Crews know it, suppliers stock it, and it’s been the standard in everything from farm layouts to residential developments. Here are the specs on pine:

- Dimensions: Typically ⅜” x 2” x 48”

- Wood Type: Softwood with long grain structure

- Flexibility: More bend than break, but can bow in the Texas sun

- Writing Surface: Wide 2” face — perfect for crews who write detailed notes right on the stake

Pine is a solid performer in soft soils, grass, or standard dirt. If you’re staking out farmland or working where the ground gives easily, pine does the job just fine. The wide writing surface is also handy when you’ve got a lot of information to record.

But here’s the rub: pine breaks a lot, especially when you push it outside those easy conditions. In compacted dirt or lime-treated soil, it splinters. In the summer heat, it warps. And when you factor in the aforementioned 15–20% breakage rate, your “cheap” stake suddenly costs a lot more than you think.

Poplar: The Modern Upgrade?...

Poplar: The Modern Upgrade?...

Poplar isn’t new to the world, but it’s relatively new to the Texas stake game — and it’s turning heads for a reason. Here are the details on polar:

- Dimensions: Slightly thicker than ⅜” x 1.75” x 48”

- Wood Type: Hardwood with a tight grain structure (think “oak-like” toughness)

- Durability: Excellent break resistance, even under punishing conditions

- Sun Resistance: Minimal bowing or warping

Poplar shines where pine struggles: compacted dirt, lime-treated foundations, caliche base. Poplar is perfect for the kind of ground that makes you sweat before you even swing the hammer. I’ve had customers send me photos of poplar stakes driven clean through asphalt. Try that with pine, and you’ll be picking splinters out of your gloves.

The tight grain structure means it holds up in the field, with less than a 5% breakage rate in the even the toughest conditions. That kind of reliability keeps your crews moving, your points in place, and your schedule intact.

It’s no wonder more contractors are making poplar “their go-to”. When the work’s hard and the deadlines are tighter, poplar lets you focus on the job (rather than wasting precious time on busted stakes).

Key Recommendations from the Experts:

After years of seeing stakes make or break a job (quite literally), here’s what I tell every contractor who asks:

- Cheaper isn’t always better: On paper, pine might seem like the budget choice. But once you factor in the breakage rate, lost control points, resurvey time, and schedule delays, it often costs more than poplar. In a 10-pallet project, poplar can save hundreds in materials alone, and that’s before you even count the labor hours you don’t lose to constant replacements. And here’s a pro tip: Because poplar breaks so much less, you can order about 20% fewer stakes than you would with pine.

- Make the choice that boosts productivity: Poplar’s durability means your crew stays in the zone, driving stakes without worrying about splintering wood or warped lines. That “flow” effect matters — especially on high-production or tight-deadline jobs where efficiency is everything. Fewer breaks mean fewer interruptions, cleaner execution, and happier crews. For maximum flexibility, many contractors mix their orders — keeping poplar as the primary stake but having some pine on hand for specialty needs.

- Get the right stake for the job at hand: Poplar is your go-to for foundation work, road construction, compacted or treated bases, and any job where speed and toughness pay off. Pine still has a place, especially in ag surveys, soft soils, or when a wide writing surface is critical. The pros keep both on hand, but lead with poplar for 95% of the work. And when you’re stocking up, use pallet pricing to drive down your per-bundle cost. Also, don’t forget to plan large jobs early so you can lock in supplies before you need them.

The bottom line is this: The stake you choose is a tool that affects your budget, your schedule, and your crew’s morale. Make it a strategic decision, and the payoff shows up in every phase of the project.

-

Order 20% fewer poplar stakes than pine (less breakage waste).

-

Mix orders for flexibility.

-

Order by the pallet for best pricing.

-

Plan large jobs early to lock in supply.

Trimble Connect: Your Top Questions Answered by the Experts

After hosting a packed webinar on Trimble Connect, one thing became clear: surveying professionals are ready to move faster, work smarter, and...

The Hidden Cost of Disconnected Workflows in 2025: How Surveyors Lose Time, Money, Sanity

In the geospatial industry, time is quite literally money. Every minute your crew spends battling data silos, transferring files manually, or...

Trimble Warranty: Everything You Ever Wanted to Know About TPP 5-Year

After years managing AllTerra Central's service department, I've seen just about everything that can go wrong with field equipment — and when it...

Rent or Buy a 3D Scanner? Make an Informed Choice in 2025

The traditional mindset of "ownership = success" is being challenged by forward-thinking survey firms discovering the strategic advantages of 3D...

How R980 IBSS Users Are Crushing Projects Others Can't Even Touch

Discover how the Trimble R980 with IBSS technology is breaking through traditional radio limitations, allowing surveyors to tackle projects of any...

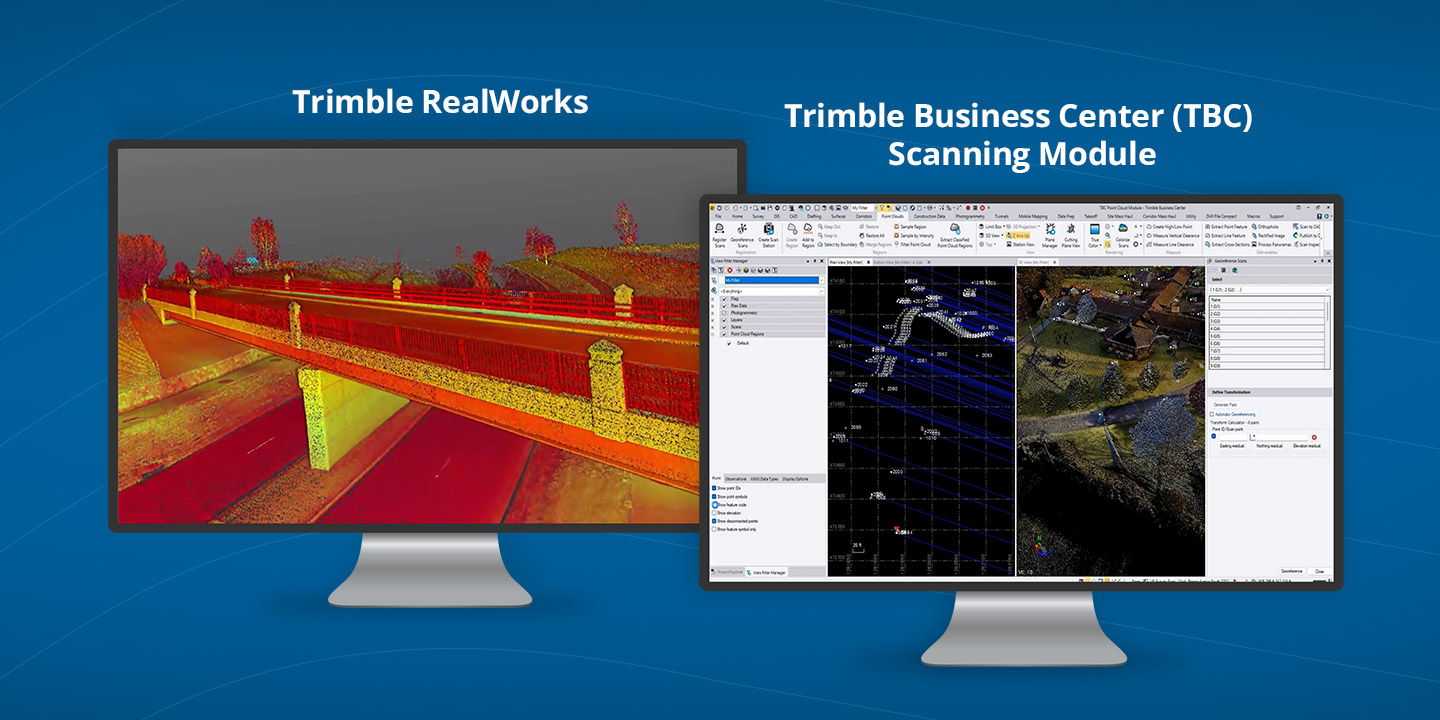

Trimble RealWorks vs. TBC Scanning Module: Which One is Best to Power Your Point Clouds?

3D scanning has rapidly evolved from a specialized technique into an essential part of modern surveying and engineering. Whether you’re capturing...

4 Critical Moments Where RTX Will Save Your Day

Every surveyor knows that sinking feeling—you're deep into a critical survey when your RTK connection drops. In these moments, RTX isn't just...

Why Aerial LiDAR is the Go-To Solution for Challenging Terrain — Backed by Real Results.

Surveying in rugged terrain is never easy. Whether it’s steep banks, dense vegetation, active mines, or remote corridors, traditional surveying...